Instructions For Use Of Wire Rope

- Storage of steel wire rope

- Handling of steel wire rope

- Inspection of steel wire rope before installation

- Unwinding and installation of steel wire rope

- Cutting of steel wire rope

- wire rope end fixing method

- Break-in operation of new wire rope

- Inspection and maintenance of wire rope

Storage of steel wire rope:

- The wire rope should storing in a clean, well-ventilated, dry, dust-free and sheltered place. To avoid direct sunlight or hot dry baking: if it can not storing indoors. It should place on a dry ground, cushion with wooden boards. And covered with a tarpaulin, and should not wetted by rain.

- When the wire rope is put into storage, the marking of the wire rope should checked. Make sure that the marking is clear and matches with the certificate of conformity.

- Wire ropes supply in spools, and when store for a long time, should turne the spools frequently. Especially in higher temperature environments, in order to avoid lubricants lost from the ropes.

- Wire rope should not stacke in multiple layers. If the rope store for a long time in large quantities, should inspect it frequently. Such as clean up the rust phenomenon in a timely manner and re-coate with lubricating grease. Such as corrosion is serious, the section of wire rope should scrapped.

- When the stored wire rope out of storage, should follow the ‘first in first out’ principle.

Handling of steel wire rope:

When handling the wire rope, it should loaded and unloaded by crane or forklift in the correct way. And the wire rope itself should not be in contact with any part of the lifting device. Such as the hook of the crane or forklift. So as to avoid damage to the rope discs and the phenomenon of chaotic coiling. And damage to the wire rope.

Inspection of steel wire rope before installation:

Check the size of the rope groove with the pulley standard gauge. To ensure that the groove can provide sufficient support for the wire rope. And there should be a certain amount of space for the rope to move freely and facilitate bending. For crane ropes, the effective diameter of the sheave groove is preferably 1.02-1.03 times the measured diameter of the rope (1.05-1.10 times the nominal diameter of the rope).

If the reel slot, the radius and pitch of the rope groove should checked. In order to ensure that it meets the requirements and can accommodate the size of the new wire rope. Never allow the actual diameter of the wire rope to be larger than the pitch of the reel.

Unwinding and installation of steel wire rope:

Wire ropes suppling in coils should unroll by placing the coil of wire rope on the ground in a straight rolling motion. And ensuring that it not contaminate by dust, grit, moisture or other harmful substances. Never allow the wire rope pull from a stationary coil. Because this will cause the wire rope to twist and form kinks.

If the wire rope coil is too large to rotate naturally, it is necessary to place the wire rope on a drop that can rotate freely so that the wire rope can pull out from the end of the wire rope coil .

Wire ropes offering on an axle with a shaft of sufficient strength threaded through the centre hole of the axle. With the axle placed on a suitable support that can rotated. And with a braking device to prevent excessive rotation during installation.

Wire rope supplier by the axle, can also using for vertical lifting of the wire rope disc to release the rope. But should pay attention to the rotational speed of the disc and the speed of the traction rope to maintain consistency. If the traction force is relatively large or fast traction, when the traction end stops. Due to the presence of inertia, the rope disc does not immediately stop rotating. At this time, wrapped around the disc of the rope on the wire rope will generate by the loosening of the wire rope, collapsed from the rope disc, it is very easy to form a kink.

The installation of the axle bracket should ensure that there is no repeated bending in the process of threading the rope. For example, to ensure that the steering of the wire rope receiving and releasing is the same. Otherwise, it is easy to collect and release the rope in the middle of the formation of the ring. Resulting in stress accumulation, resulting in the wire rope not use on the scrap.

When multiple layers of ropes in wound reel, the supply rope spool should place on a device that provides counter-tension to the ropes. So that the counter-tension can transfer from the spool to the reel. Thus ensuring that the lower layers of ropes, and in particular the bottom layer of ropes, tightly wound on the reel.

The supply wire rope spool should mounted in a suitable position to ensure that the angle of the wire rope deflection keep within a suitable range during installation. The angle of α should be less than 1.5° for ungrooved reels and less than 2.5° for grooved reels. This angle is also applicable to the wire rope running system .

Control must exercise when untying the end of the wire rope from the supply spool or the outside of the reel. When the end of the rope relase from the restraint or fixed, the rope will automatically straighten due to its own elasticity. And if left uncontrolled, the rope will snap open violently, possibly causing injury.

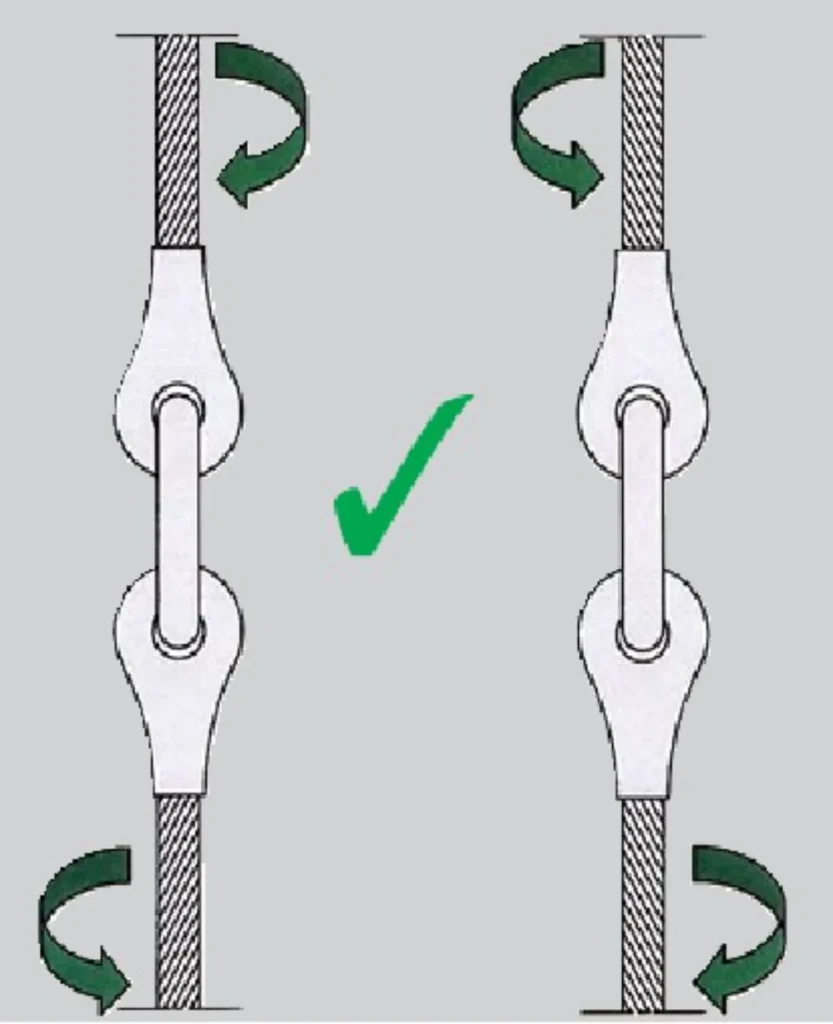

Whether during installation or during operation, when it is necessary to connect one wire rope to another (i.e., in series). These ropes must have the same twisting direction and type, e.g., the right cross-twist must connect to the right cross-twist. If the ‘left’ twist wire rope and ‘right’ twist wire rope connected together, when there is a load will cause the rope to rotate or strand loose twist. If the ropes braided by hand, the braided joints will come loose or pull out.

The wire rope should kept in the condition in which it manufactur during installation.

If a new rope is install with the aid of an old rope. One method of connecting the new rope to the old rope is to fit a sleeve over the end of the new rope and the old rope. The open end of which should securely affixed to the wire rope by means of a covering or a suitable clamp. The ends of the ropes then connected by a fibre rope of sufficient strength to avoid rotation transmitted from the old rope to the new. If a wire rope connection is use, a rotation-resistant rope or a new rope with the same type and direction of twist should using. Alternatively, as a replacement, a fibre or steel rope of sufficient strength may threaded into the system for use as a control or suspension line. Swivel joints shall not used in the installation of wire rope.

The rope should carefully monitored as it drawn into the system to ensure that not obstructed by any part of the structure. Or mechanism that could damage the rope and cause loss of control.

Whether it is a smooth or grooved reel, the winding direction of the wire rope on the reel should be in accordance with the ‘left and right hand rule’.

Cutting of steel wire rope:

If it is necessary to cut off the wire rope, the wire rope should tied at both ends of the cutting mark first. For the diameter of not more than 100mm single stranded wire rope at both ends of the cutting mark at least one tie. Each length is not less than 2 times the diameter of the rope. For the multi-stranded wire rope and the diameter of more than 100mm single stranded wire rope in the cutting mark of the ends of the at least two ties. Each length is not less than 2 times the diameter of the rope.

wire rope end fixing method:

Fixed with wire rope clips

Wire rope wedge fitting fixing

Break-in operation of new wire rope:

If possible, through the low-speed operation of the equipment break-in operation of the new wire rope. Preferably in a relatively low load cycle for a certain number of times. So as to ensure that the new wire rope can self-adjustment to gradually adapt to the working conditions. But never allow in full load or overload conditions on the wire rope break-in operation. Carefully check to ensure that the wire rope correctly coiled on the drum. The wire rope on the drum without slack or cross overlap phenomenon occurs.

Inspection and maintenance of wire rope:

- Crane wire rope inspection, periodic comprehensive inspection and scrapping standards, should follow. Crane wire rope Maintenance Maintenance Installation Inspection and scrapping – GB/T5972.

- Wire rope in the process of use, should be in accordance with the relevant provisions of the periodic inspection. And will be the results of the inspection to make a good record of the contents of the inspection should include the following items. The degree of wear and tear of steel wire, wire breakage, lubrication. Rope connecting part or not the end of the fastening part, and other anomalous phenomena.

- In order to obtain the best performance, most of the wire rope in the use of the period need to supplemented with oil. The lubricant must coated with the original lubricant during the manufacture of the same. And for the traction drive rope coated with lubricants shall not reduce its friction properties.

- Typical oiling methods during use are oiling with a brush, dripping oiling, portable pressure spray oiling or high-pressure spray oiling. The latter method involves power jetting the lubricant into the wire rope under high pressure. Which can simultaneously clean the wire rope and remove moisture, residual grease and other contaminants.

Comments

Post a Comment

Stay in touch with us and get the latest updates from the lifting and material handling industry