What type of rope is best for mooring lines?Technical Knowledge Sharing

When choosing the mooring ropes, it’s essential to consider strength, durability, and resistance to the harsh marine environment. The most commonly recommended types of rope for mooring are polyester ropes and nylon ropes. Polyester preferred for its excellent resistance to UV rays, water absorption, and low stretch properties. Making it ideal for maintaining tension on mooring lines. Nylon, on the other hand, offers excellent shock absorption and strength, which is ideal for boats and ships exposed to varying forces. Additionally, ropes with braided or twisted constructions often chosen for their flexibility and ease of handling. Our engineers will explain in detail the types, uses and materials of mooring lines.

- Advantages

- Material

- Applications

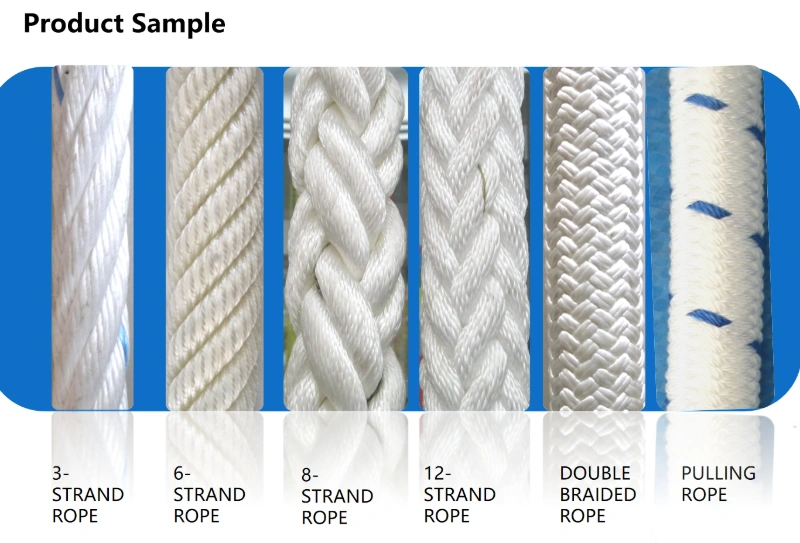

- Types

1、3-Strand Polypropylene(Pp) Filament Yarn Rope

- Structure:3-strand

- Material:Polypropylene(pp)

- Application:Shipbuilding, ocean transportation, fishing, port operation, etc.

- Product Performance:Polypropylene filament rope, made of industrial high strength polypropylene filament. Therefore, technical performance has reached the international standard lever of ISO1346-2012. Besides, it has high strength, reasonable price, high performance cost effective. Polypropylene filament yarn is carbon chain polymer compounds, with high stability of acid, alkali, and antioxidant, is of high chemical resistance capacity, density is 0.90-0.92g/cm3. It’s the lightest fiber with high floatability, soft character, smooth hand feeling. As well as easy operation, good electrical insulating property, goods antimicrobial property, no mold, no decay, and other advantages.

2、8-Strand And 12-Strand Polypropylene(Pp) Filament Yarn rope

- Structure:8-strand and 12-strand

- Material:Polypropylene(Pp)

- Application Areas: For example, shipbuilding, ocean transportation, fishing, port operation, etc.

- Product Performance:Polypropylene filament rope, made of industrial high strength polypropylene filament, technical performance has reached the international standard lever of ISO1346-2012. It’s high strength, reasonable price, high performance cost effective. Besides, Polypropylene filament yarn is carbon chain polymer compounds, with high stability of acid, alkali, and antioxidant, is of high chemical resistance capacity, density is 0.90-0.92g/cm3. It’s the lightest fiber with high floatability, soft character, smooth hand feeling, easy operation, good electrical insulating property, good anti-microbial property, no mold, no decay.

3、3-Strand Polypropylene Monofilament Rope

- Structure:3-strand

- Material:Polypropylene

- Application Areas:Mainly used in ship mooring, marine fishing, and mariculture, etc.

- Product Performance:The rope making of monofilament polyethylene. And it’s of light density, good floatability, chemical corrosion resistant, nonabsorbent, good electrical insulating property, excellent quality, and reasonable price.

4、8-Strand And 12-Stand Polypropylene Monofilament Rope

- Structure:8-strand and 12-stand

- Material:Polypropylene Monofilament Rope

- Application Areas:Mainly used in ship mooring, marine fishing, and mariculture, etc.

- Product Performance:The rope is making of monofilament polyethylene; and it’s of light density, good floatability, chemical corrosion resistant. As well as nonabsorbent, good electrical insulating property, excellent quality, and reasonable price.

5、3-Strand Polyester Rope

- Structure:3-strand

- Material:Polyester

- Application Areas: Such as mooring of the vessel, ocean transportation, port operation, military industry and mining pulling.

- Product Performance:Use high-grade Polyester filament for industry as material. It’s abrasive resistance ability rank after nylon, but far higher than other fibers. It’s with stable chemical properties, high acid resistant ability. As well as good anti-stretch capacity, good stiffness, aging resistant. Besides, the UV resistance, heat resistance, mold resistance, no water absorption, not easy to deformation, soft appearance, good feel, high strength, long service life and other advantages

6、8-Strand And 12-Stand Polyester Mooring Rope

- Structure:8-Strand And 12-Stand

- Material:Polyester Mooring Rope

- Application Areas: For example mooring of the vessel, ocean transportation, port operation, military industry and mining pulling.

- Product Performance:The rope use the material of high-grade Polyester filament for industry. It’s abrasive resistance ability rank after nylon, but far higher than other fibers. Therefore, it with stable chemical properties, high acid resistant ability, good anti-stretch capacity. Also has good stiffness, aging resistant, UV resistance, heat resistance, mold resistance, no water absorption, not easy to deformation. As well as soft appearance, good feel, high strength, long service life and other advantages

7、8-Strand And 12-Stand Double Fiber Braided Mooring Rope Of Polyester And Polypropylene

- Structure:8-strand and 12-stand

- Material:Polyester and polypropylene

- Application Areas: Mainly used in vessel mooring, towage, oil exploration and traction, etc.

- Product Performance:This rope is making of the mixture of polyester and polypropylene. Additionally, the outside layer covering with polyester fiber to gain the prominent wear-resisting effect. The strength is higher than polypropylene and polyester mooring rope. Compared with Nylon rope, the weight is light to float on the water with the properties of low elongation. As well as good wear resistant capacity, soft, easy to operate, UV resistant, long lift, etc.

8、8-Strand And 12-Stand Double Fiber Braided Mooring Rope Of Polyester And Polyolefin

- Structure:8-Strand And 12-Stand Double Fiber Braided

- Material:Polyester and polyolefin

- Application Areas: Such as shipbuilding, ocean transportation, national defense scientific research, port operation, anchoring and towage, etc. (White is the standard color, and other colors can be customized).

- Advantages: High strength, light density, floating on the water, corrosion-resistant, seawater resistant, soft, nonabsorbent, UV resistant, good wear resistant and long life, etc.

- Product Performance:It’s made of the mixture of polyester and polyolefin fiber with special producing technology. The outside layer of rope is covered with polyester fiber 40% at least which to improve the wear-resistant capacity. The inside of rope is made up of 100% high strength polyolefin fiver.

9、3-Strand Polyamide (Nylon)Mooring Rope

- Structure:3-strand

- Material:Polyamide (nylon)

- Application Areas:Widely used in large ships, warships towing, oil exploration, fisheries, mining, etc.

- Product Performance:Polyamide commodity called Chinlon, also called Nylon. Polyamide mooring rope is mainly made by Nylon#66. Polyamide multifilament density is 1.12-1.14g/cm3, polyamide mooring rope is with high strength, good wear-resisting capacity, high alkali resistance performance, high resilience foam. It can 100% spring back when being extended 3%.

10、8-Strand And 12-Strand Nylon Mooring Rope

- Structure:8-strand and 12-strand

- Material:Nylon

- Application Areas:Widely used in large ships, warships towing, oil exploration, fisheries, mining, etc.

- Product Performance:Polyamide’s commodity name is called Chinlon, also called Nylon. Polyamide mooring rope is mainly made of Nylon #66. Thedmultifilament density of it is 1.12-1.14g/cm, which is of high strength, good wear-resisting capacity, high alkali resistance performance, high resiliencelfoam. It’ s 100% spring back rate when extending 3%.

11、8-Strand And 12-Strand Aramid Fiber Mooring Rope

- Structure:8-strand and 12-strand

- Material:Aramid fiber

- Application Areas:Mainly used in the field of high temperature, chemical, fire-fighting. Mooring rope for chemical tanker and oil tanker. Paratroopers cable, the national defense scientific research, power engineering and other situation of low or high temperature, etc.

- Product Performance:Aramid fiber mooring rope is made by the high tension, high modulus, high performance, high temperature resistancel fiber, which is mainly Aromatic copolymer acyl ammonium fiber, can add protective sleeve on the rope body according to customer requirements, to increase the wear resistance capacity. Products is of high breaking strength, good heat resistance capacity, will not fuse under high temperature. Good fire-resistant capacity, which can self-extinguish. Acid and alkali resistance, ageing-resistance, and radiation resistance, etc.

12、8-Strand And 12-Strand UHMWPE Mooring Rope

- Structure:8-strand and 12-strand

- Material:UHMWPE rope

- Application Areas:Mooring, anchoring, lifting sling, towage, military industry, ocean oil, and ocean transportation, etc.

- Product Performance:UHMWPE mooring rope of eight-strand and twelve-strand are produced after resin treatment of the yarn with the international advanced technique. Protection sleeve can be added according to customer’ s requirements, which can improve the wear-resistant capacity. As to the strength, it is higher than the steel wire rope with the same diameter, but the weight is only 15% of the wire rope. Low elongation at 3.5%-4.5%. Density is 0.97g/cm, which can make sure it can float on the water. Soft, UVresistant, good bending and anti-fatigue capacity, fatigue resistance strength is 1000 times of that of steel wire rope and Nylon rope.

13、Double Braided Mooring Rope

- Structure:Double braided

- Material:Polypropylene (pp),Polyester (terylene),Polyester/ polypropylene mixed

- Application Areas:Mainly use in Ocean transportation, Shipbuilding, Oil exploration, National defense military industry, port operation, and Ocean engineering, etc.

- Product Performance:We apply advanced international technology. Inside is core rope, outside layer is braided sleeve, to protect the inside core rope. The surface is round and smooth, soft, and beautiful, which has improved the rope comprehensive performance. According to the material, it is divided into multifilament polyamide, multifilament polypropylene, multifilament polyester, multifilament polyester/polypropylene. Character: wear resistant, seawater resistant, chemical resistant, aging resistant, high temperature resistant, elongation is lower than normal rope, easy to be operated, etc.

Types of Double Braided Mooring Rope:

- Polypropylene (pp) double braided mooring rope

- Polyester (terylene) double braided mooring rope

- Polyester/ polypropylene mixed double braided mooring rope

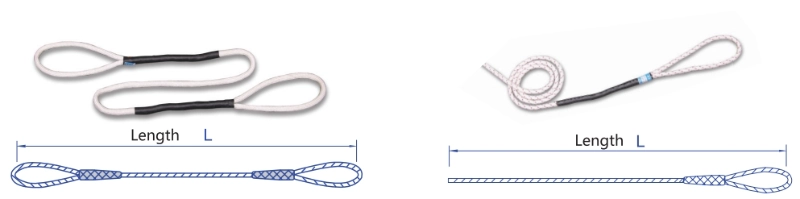

14、High Performance Traction Rope

- Material:Polyester (terylene),UHMWPE rope

- Application Areas:Mainly used in power installation, transportation, navigation, water sports, and aviation, etc.

- Product Performance:The inside core rope is made of high-tension multifilament polyester yarn or UHMWPE; the outside is covered by polyesterprotection sleeve. The advantages: light, sot, high safety factor, long lifetime, non-conductive and good corrosion resistance capacity,etc.

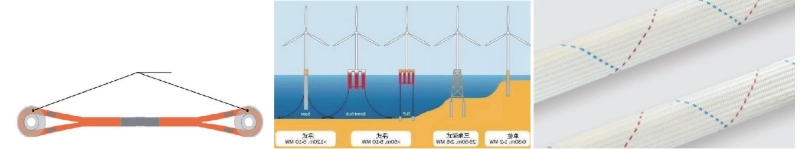

15、Deep Sea Mooring Rope

- Structure:The core bearing structure is composed of parallelthree-strand rope or twelve-strand rope, the braided layer and the bearing core are covered with a sand-proof layer.

- Material:The material could be polymerase, polypropylene, polyamine, UHMWPE, etc.

- Application Areas:Used for long-term mooring of offshore oil and gas production platforms, floating wind turbine generator, deep-sea aquaculture equipment, marine energy power generation, deep-sea buoys and other devices and structures.

- Product Performance:Deep-sea mooring lines have a life of 7-15 years without protective coating. When the rope is covered with protective coating, the joint with sacrificial anode and other anticorrosion measures, the life of deep-sea mooring ropes can be 15-30 years.

Important Factors For Accurate Mooring Line Selection

Choosing the right mooring line is crucial to ensuring the safety and stability of a vessel during docking or anchoring. Several key factors should be taken into account to ensure the selected line meets the requirements of the vessel and its operating environment:

- Strength and Load Capacity

- Material Type

- Durability and Environmental Resistance

- Stretch and Elasticity

- Diameter and Length

- Construction Type

- Mooring Line Handling

- Shock Absorption

- Safety Standards and Certifications

- Cost

Why choose mooring lines from KNKT?

- Scope of production: The construction of cables can be divided into 3, 6, 8 and 12 strands. Raw materials include: polypropylene, polyester, nylon, UHMWPE, aramid fibres and synthetic fibres. Diameter range: φ6mm ~ φ140mm.

- Advantages of mooring ropes: High tensile, low elongation, anti-friction, corrosion resistant, soft and smooth, easy to handle, etc. Mooring lines are mainly used in marine equipment, fishery, port work, power construction, oil exploration, national defence and sporting goods.

- Factory Strength: Mooring lines manufacturing factory covers an area of 10,000 square metres, with an annual production capacity of 6,000 tonnes and 120 employees, including 10 professional technicians.

- Certifications: The products have passed a series of authoritative certifications such as China Classification Society ccs certification, American Bureau of Shipping abs certification, British Bureau of Shipping lr certification, French Bureau of Shipping bv certification, German Bureau of Shipping gl certification, Det Norske Veritas dnv certification and so on.

Seeking Mooring Rope Solutions?

With over 30 years of experience in the production and manufacturing of mooring lines, our factory is equipped with advanced, state-of-the-art machinery. We hold various certifications and standards to ensure the highest quality products. Our extensive export experience allows us to meet the needs of clients worldwide. For more information or any inquiries regarding mooring ropes, please feel free to contact our engineers. We’re here to provide you with expert advice and solutions tailored to your requirements.

Comments

Post a Comment

Stay in touch with us and get the latest updates from the lifting and material handling industry