Compacted Steel Wire Rope Solutions: Maximize Strength and Reliability for Cranes, Offshore, and Industrial Use

Introduction

Compacted wire rope is a specialized type of steel wire rope designed to deliver higher strength, smoother surface, and improved abrasion resistance compared to conventional ropes. Through a unique compaction process, the strands compressed to reduce voids and increase metallic cross-section, resulting in exceptional performance for demanding lifting, hoisting, and offshore applications. For engineer seeking or buying high-strength compacted wire rope, understanding its manufacturing process, benefits, and uses is essential.

What Is Compacted Steel Wire Rope?

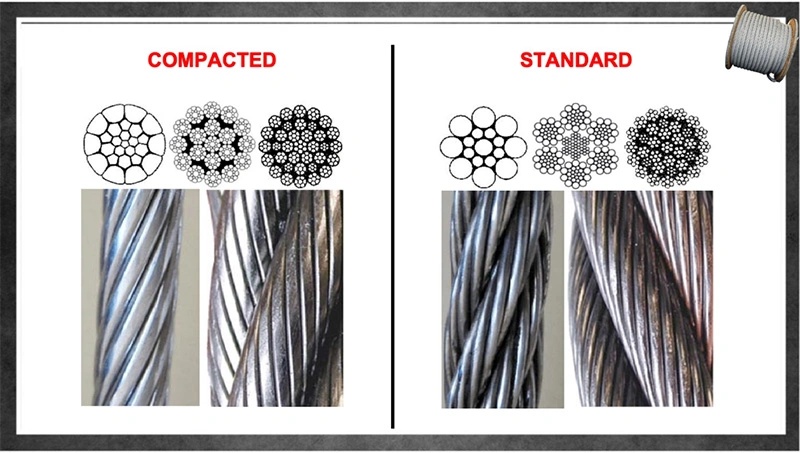

In a standard wire rope, individual wires and strands are laid together, leaving small gaps and voids. During operation, these voids can lead to increased internal friction, higher wear, and reduced fatigue life.

Compacted wire rope solves this problem by compressing the strands or the entire rope using high-pressure rollers or dies. The result is a rope with:

- Denser metallic structure

- Higher load-bearing capacity

- Smoother outer surface for reduced sheave wear

- Improved resistance to crushing and flattening on drums

How Compact Wire Rope Manufactured?

The manufacturing process typically follows two main methods:

Strand Compaction

Each strand of the rope is compacted individually before closing. This method ensures that outer wires reshaped into a more uniform profile, reducing gaps and creating a stronger strand.

Rope Compaction

The rope is first closed (laid up), then passed through compaction rollers or dies. This compresses the entire rope, further enhancing density and surface smoothness.

Advantages of Compaction:

- Increases metallic cross-section area (more steel per diameter)

- Enhances breaking load capacity (up to 15% higher than standard rope)

- Provides smoother running over drums and sheaves

- Extends fatigue resistance under repeated bending

Compacted/Compressed Wire Rope vs. Standard Wire Rope

| Feature | Standard Wire Rope | Compacted Wire Rope |

| Strength | Normal breaking load | Up to 15% higher |

| Surface | Rough, more friction | Smooth, less wear on sheaves |

| Durability | Prone to internal movement | Reduced wire movement, longer life |

| Winding | Higher risk of crushing on drums | Excellent resistance to crushing |

| Cost Efficiency | Lower upfront cost | Longer lifespan, lower lifecycle cost |

Benefits of Compacted Wire Rope

- Higher Breaking Load

- Stronger than conventional ropes of the same diameter.

- Enables downsizing (smaller rope with equal strength), saving weight in crane and offshore applications.

- Extended Service Life

- Reduced internal movement minimizes fatigue and wear.

- Lower replacement frequency reduces downtime.

- Superior Abrasion Resistance

- Smooth outer surface prevents premature sheave and drum wear.

- Better Drum Winding Performance

- Compact cross-section allows tighter, more uniform winding.

- Reduced “flattening” and “birdcaging” effects.

- Versatility Across Applications

- Suitable for cranes, elevators, cableways, offshore winches, and mining hoists.

Common Structures of Compacted Wire Rope

- 6×K36 IWRC Compacted: A balance of strength and flexibility, commonly used in cranes and winches.

- 8×K26 IWRC Compacted: Increased flexibility, suitable for offshore and port winches.

- 35W×K7 Compacted Rotation-Resistant Rope: Designed for tower cranes, mobile cranes, and lifting tasks requiring minimal rope spin.

- 19×K7 Compacted Wire Rope: Frequently used in elevators and hoists.

Each construction offers unique benefits. Selecting the correct rope type depends on load, lifting equipment, working environment, and safety standards.

Wide Applications of Compact Wire Rope

By sourcing from a trusted compacted wire rope supplier, buyers gain access to certified products ready for safety audits and compliance checks.

- Cranes and Hoisting

- Tower cranes, crawler cranes, mobile cranes

- Luffing and hoist ropes requiring strength and flexibility

- Mining Industry

- Draglines, mine hoists, and winches

- Withstands high load cycles and abrasive environments

- Offshore and Marine Operations

- Mooring, towing, and subsea lifting

- Certified for compliance with OCIMF, API, and ISO standards

- Construction and Elevators

- Cableways, lifts, and elevators requiring high safety margins

Choosing the Right Compacted Wire Rope Manufacturer Supplier

When purchasing compacted wire rope, buyers should consider:

- Certification: EN 12385, ISO, API, DNV, ABS approval where required.

- Breaking Load Charts: Ensure compliance with design requirements.

- Customization: Diameter, length, and surface coating (bright, galvanized, plastic-coated).

- After-Sales Support: Technical datasheets, inspection manuals, and quick delivery.

👉 Our company provides ISO-certified compacted wire ropes tailored for cranes, offshore platforms, mining operations, and construction projects.

Request a technical datasheet or quotation today to secure a reliable solution for your next lifting operation.

Comments

Post a Comment

Stay in touch with us and get the latest updates from the lifting and material handling industry